1 - 250 Horsepower Rotary Screw Air Compressors

What is a rotary screw air compressor?

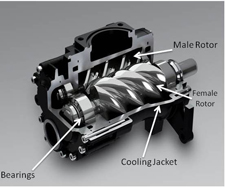

A rotary screw air compressor is one of the most widely used technologies in industry and is the workhorse behind many processes and applications. Rotary screw technology is superior for reliability and 24/7 continuous run availability with no duty cycle. Rotary screw air compressors use 2 screws/rotors, 1 male and 1 female, to compress air through a continuous motion. Helical lobes attached to the shafts of the screws trap and compress the air then discharge it from the airend. The air is then passed to a separator and coalescent filters that remove most of the oil from the air, usually down to 2-5 ppm.

Why purchase a rotary screw air compressor?

- deliver a continuous flow of air.

- operate in extreme temperatures.

- run tools efficiently that require high air flow.

- fewer parts to service than piston air compressors, lowering maintenance costs.

- QUIET, yet provide massive air flow.

- generally energy efficient and generate less heat than piston machines.

- less oil consumption than other flooded machines with minimum oil carry over.

- years of service with no capacity reduction.

|

|